Assignment 2 - The Ferrari 250 gto

My group members:

Jiayu Li http://jiayuli5027232.blogspot.com.au/

Shanshan Zhang http://zhangshanshan.blogspot.com.au/

Qiutong Zhang http://kiwisferrari.blogspot.com.au/

Ruilin Qin http://qinruilinbeil0014.blogspot.com.au/

Zhenlei Yu http://zhenleiyubeil0014.blogspot.com

Qian Sha (me)

Step 1:

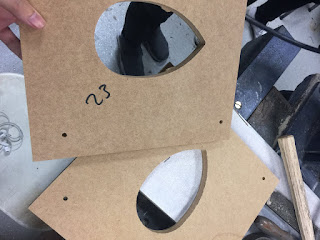

Export the component of the template from the model of Ferrari in

123dMake and change the document into the Illustrator file for laser cutting. Step 2:

Step 3:

Place masking tape and tracing paper on the template to make the surface

of template more flat and smooth.

Step 4:

Divide the car into different parts and

trace the shape of each part on tracing paper. Stick the tracing paper on the

aluminum sheet and cut it according to the shape of the tracing paper. It was

cut a little bit wider than the line on tracing paper so that there’s some

flexibility of adjusting the shape after striking it.

Step 5:

We divide the car into several parts

including: top of the car(from empennage to windscreen), top cover, the

front face, right front above wheel, right back above wheel, left front above

wheel and left back above wheel, and I’m responsible for the top cover of the

car.

The top cover is basically a large

rectangular slightly bent and have a linear bulge in the middle.

Firstly I place the sheet on the template and slightly beat the part surround the bulge to affirm the location of the bulge.

After confirming where is convex, I strike it from the back with the sharp end of the hammer on the sandbag to increase the bulge.

Then use the bigger end of the hammer beating the other part of the sheet to get the bending trend. Always check the bending degree with the template to avoid over bending.

To sharpen the edge of the bulge, I use a wood template with sharp edge.

Use the English wheel to smooth the surface of the sheet and remove the concave by the hammer.

Place the top cover on the template together with adjacent portion to adjust the edge and make them better match. Cut off the useless part and sand the edge with the metal file.

Finally polish the surface with metal polish liquid to get a beautiful finish.

Final product with every component assembled.

评论

发表评论